240K

240K

Europlast’s latest innovation sets new standards with sustainable production using up to 100% recycled materials.

Recycling based on renewable energy reduces the 240K’s CO2 footprint across the entire production chain

RESOURCE SAVING

Through production of recycled material in our in-house shredding facility

EMISSION REDUCING

Through reuse of materials

FUTURE ORIENTED

Through CO2 savings and sustainable production

Increased transport capacity by up to 10%

Optimised stacking enables more efficient transport

Surprisingly quiet

MAXIMUM PERFORMANCE WITH MINIMAL NOISE

- The patented spring design and

- patented lid brake make it possible

NOISE REDUCTION

BY UP TO 20%

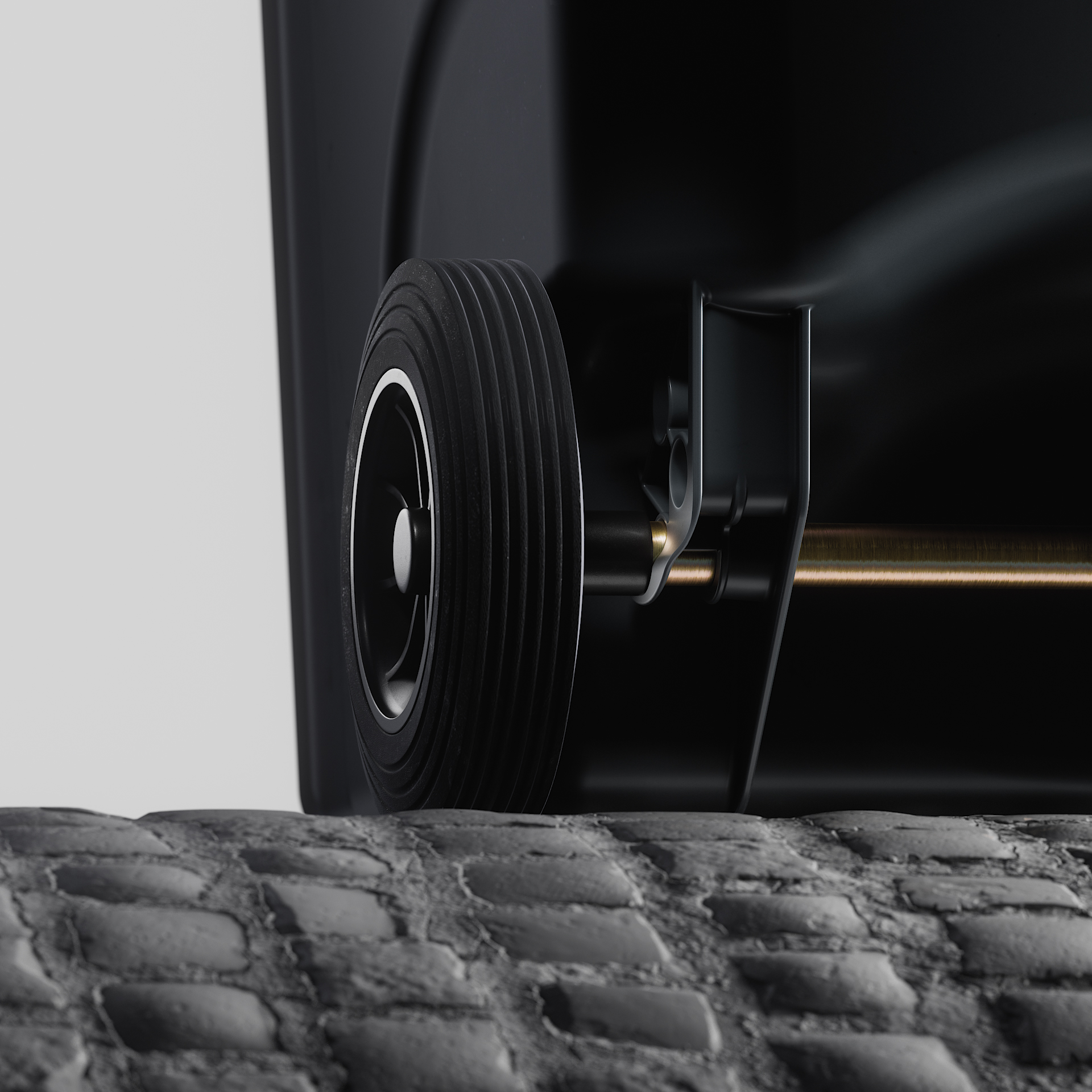

The patented spring in the wheel area makes our 240K surprisingly quiet

The patented spring design prevents uncontrolled movement of the wheel

ADDITIONAL NOISE REDUCTION THROUGH PATENTED LID BRAKE

By slowing the lid, the impact noise on the back of the container is reduced

The patented lid brake slows down opening and closing

Wind-optimised lid design

The innovative lid design prevents unintentional opening

Hygienic design and maximum comfort

COMFORT STANDARDS

- More efficient handling

- More legroom

- Hygienic handles

- Enlarged base radii

Larger grip area

for easier handling with gloves

Extended foot entry

for comfortable tilting

Clean Touch handles

for hygienic handling

Optimierte base radii

for a clean emptying process

Longevity through increased stability

DURABLE THROUGH INNOVATION

- Solid beads

- Patented reinforcement bar

- Patented comb spring

- Patented lateral spring

- Robust reinforcement ribs

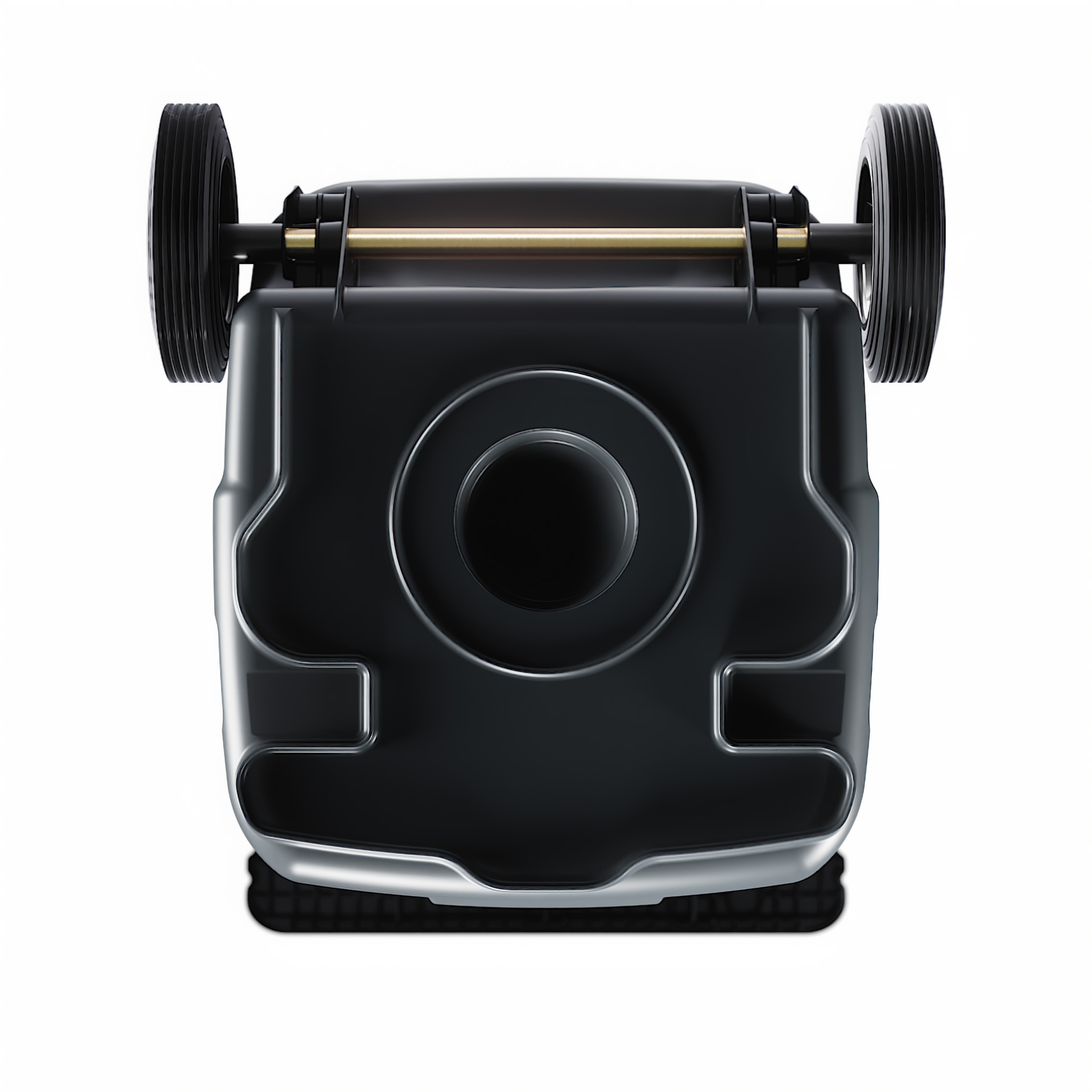

- Reinforced axle construction

Solid front- and side beads

cushion the forces acting on them

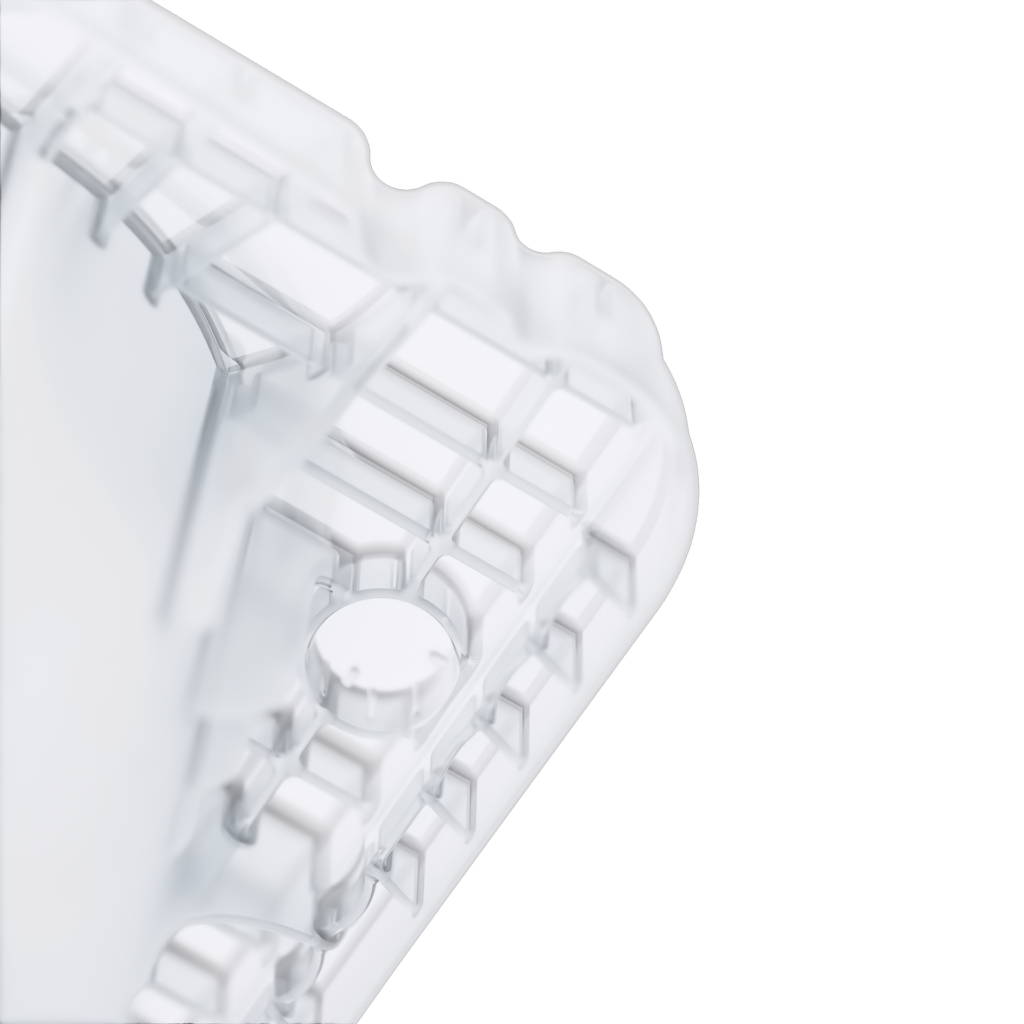

The patented double reinforcement bar

significantly increases comb strength

The patented spring design

prevents the comb bar from overstretching

The patented lateral spring

prevents the comb bar from overstretching

Robust reinforcement ribs

reduce wear on the underside of the container

The reinforced double rib

increases the strength of the axle bearing

Into the future

RFID integration

Enables customer-specific identification of recycling containers and optimises collection, monitoring, and management in waste disposal

Easily integrated

In-mould

Chip nest

Handle bar

As unique as your company

Europlast enables customisation of the container using specialised processes

Lid clips

Innovative solution to colour-code recycling containers by fraction

Dimensions

734mm

406mm

734mm

406mm

734mm

1034mm

734mm

1034mm